-

Game Changing Technological Innovations in

MELT COMPOUNDING

Transforming an extruder into a mixing vessel! How to archive this with the compounder having supreme ability to control the work carried out the time spent?

-

DISTINGUISHING FEATURES of

HIGH PERFORMANCE TSEs

Innovative and functional design improvements that provide real process solutions are the need of the hour. Modern high performance extruders are distinguished by their special features.

-

ENHANCING

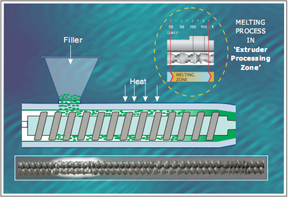

MELTING AND MIXING capabilities in a Twin-Screw Extruder

Melting and Mixing are the two giant (meteoric) steps that take place inside the Extruder Processing Zone(EPZ) of a co-rotating twin-screw extruder. Enhancement of melting and mixing is the key to archive some extraordinary results.

-

Here’s a New & Specialized ChromoXX-PVD Coatingfor Elements in TSEs

Over a many years of plastic processing using co-rotating twin-screw extruders, wear of screw elements has always been a cost factor for the plastic industry. with plastic processing becoming more demanding,

-

THE FAST GROWING ‘WOOD PLASTIC COMPOSITES’ - WPC

The term “wood plastic composite” (WPC) refers to any composite that contains wood and thermoset or thermoplastic. Thermosets include resins such as epoxies and phenolics. Thermoplastics include resins such as polyethylene,

-

THE HEART OF A TWIN SCREW EXTRUDER IS EPZ

The Extruder Processing Zone (EPZ) is the ‘heart’ of a Co-rotaing Twin-Screw Extruder that helps to archive the desired performance. Work done in the desired quality of compounded material and levels of output in a co-rotating twin-screw extruder

-

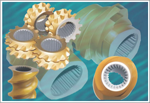

CONFIGURATION OF SCREW ELEMENTS IN EPZ!

The adage ‘different stokes for different folks’ holds good when one attempts to deal with the EPZ of a Co-rotating Twin-Screw Extruder. Within this EPZ area the ‘key to success’ lies with the exact design of the ‘Element and Barrel’ Configuration.

-

SFV ELEMENTS

The earliest co-rotating twin-screw extruders had shallow flight depths and were designed to be run with a filled-uop hopper, in the same way an injection-molding machine or a single-screw extruder is run.

-

THE ‘ART OF COMPOUNDING THERMOPLASTICS’

When there are hundreds of different types and varieties of polymers, why use an additional process called Compounding? The answer is very simple. Most of us begin our day by using a compounded product.

-

FRACTIONAL ELEMENT GEOMETRY

Co-rotating twin-screw extruders have evolved through the years. Deeper flights lead to increased efficiencies and reduced shear rates in a twin-screw extruder. This feature is advantageous in increasing the screw speed thereby maintaining mixing rates and increasing the volumetric capacity of the machine.

Home > Featured Articles